The strength of steel chains

Steel chains are characterised by their versatility in the face of the different challenges posed by the various applications of steel chains. That's why, in this article, we look at the strength levels of steel chains and our range of UNIQ chains.

Steel chain grades

The different grades of steel chain offer a wide range of options to suit different applications and environments. Identified by an alphanumeric designation, such as G30, G70 and G80, each grade represents the strength limit of the chain, expressed in newtons per square millimetre. For example, grade 80 (G80) indicates that the chain can withstand a maximum load of 800 Newtons per Square Millimetre.

The choice of chain grade depends on the type of application and specific strength requirements. For instance, UNIQ Grade 80 chains are ideal for overhead lifting applications due to their high strength and load capacity.

In terms of safety regulations, chains must have a minimum elongation of 20%, and alloy components are used in their manufacture to ensure that alloy chains consistently meet this requirement.

This ensures that the chains maintain their structural integrity and strength even under heavy loads and demanding conditions, providing increased safety and durability in a variety of industrial and lifting applications.

UNIQ steel chain range

The UNIQ steel chain range offers even more options to meet the specific needs of a wide range of industries and environments. From commercial to grade 80, we highlight their features, applications and tips to maximise their performance.

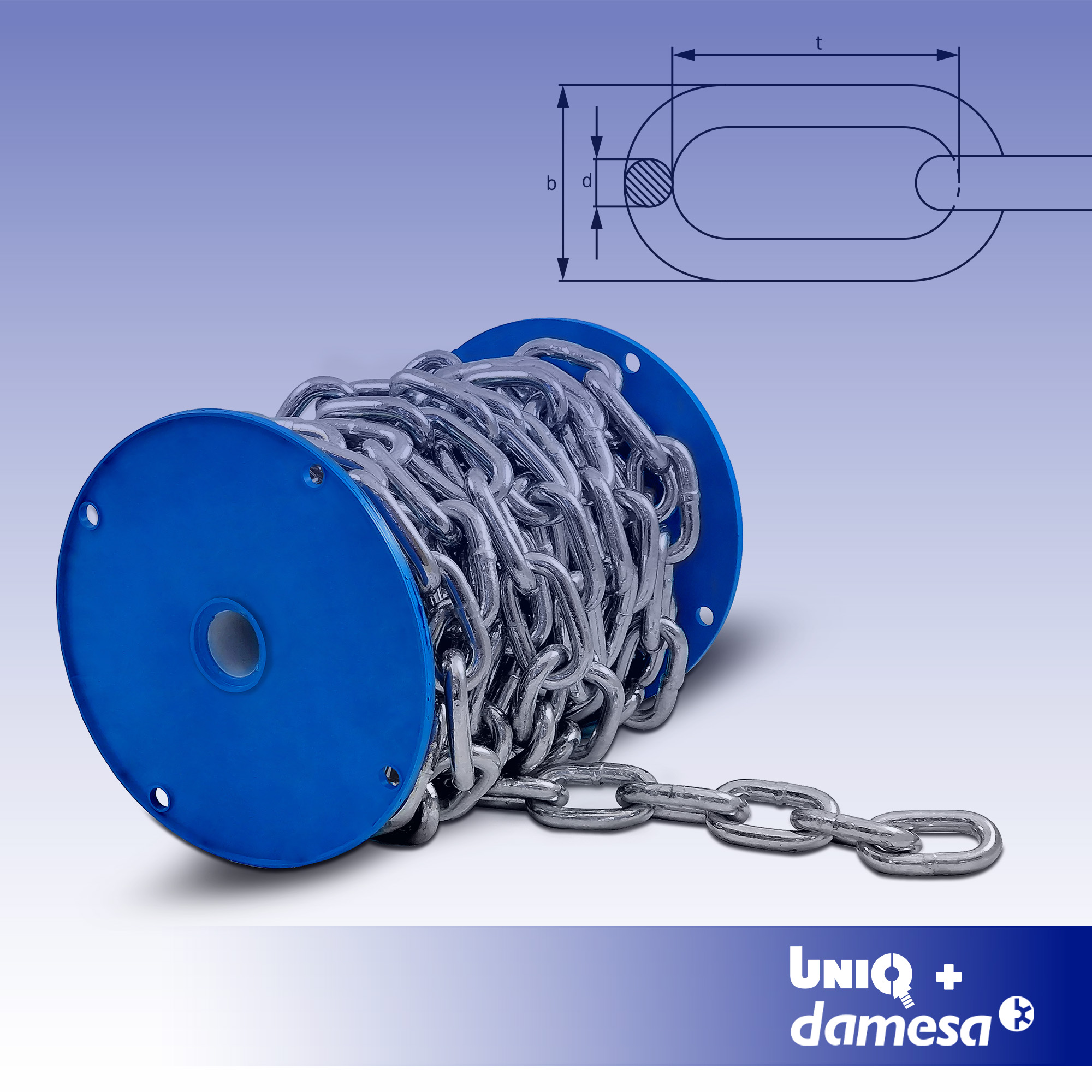

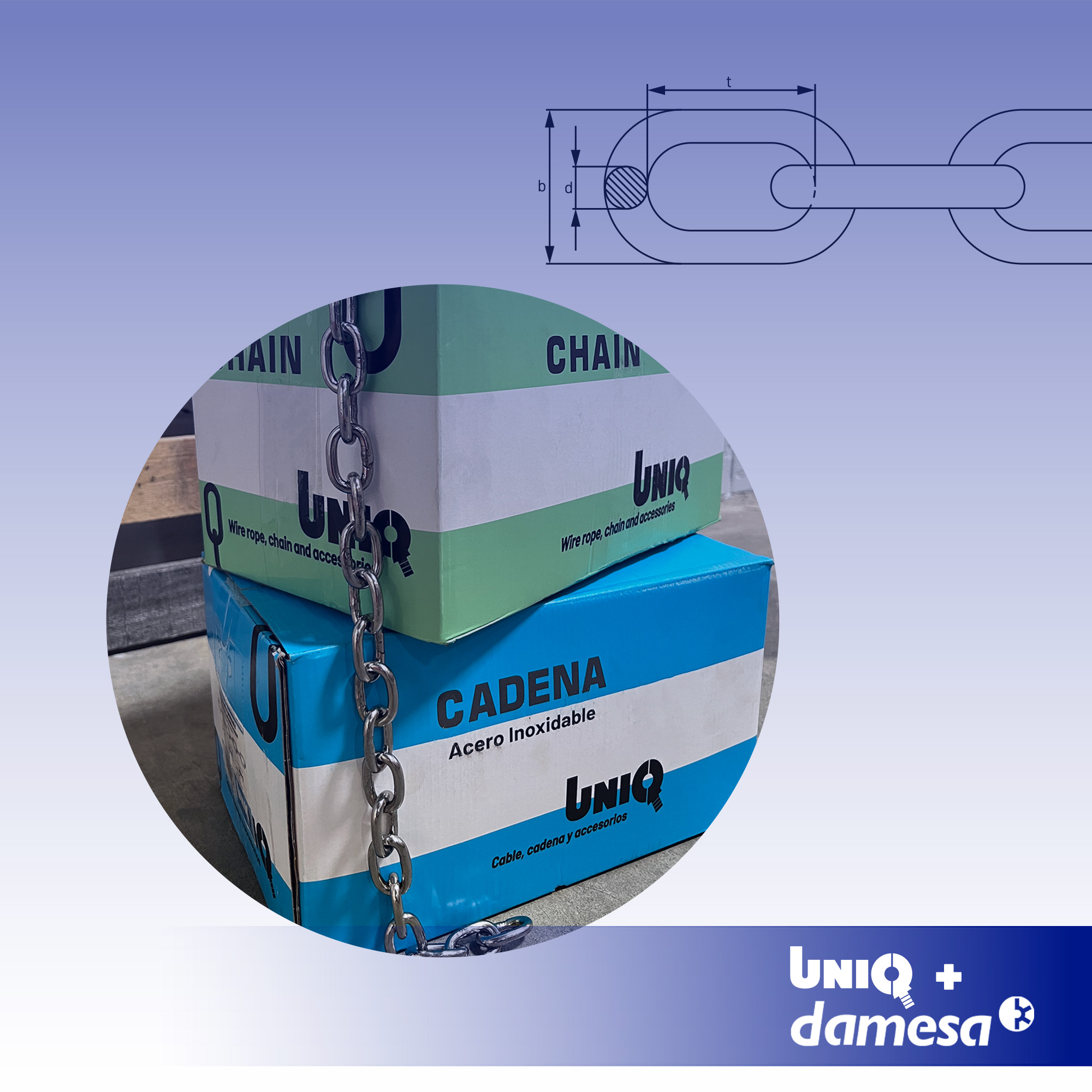

1. UNIQ commercial chain:

UNIQ commercial chain is the ideal choice for common and universal applications where reliable strength and consistent performance are required. Its straight design and robust construction ensure a perfect fit and exceptional durability in a variety of industrial and commercial environments. UNIQ commercial chain is manufactured from stainless steel banding and features a galvanised finish for superior corrosion resistance.

Key features:

- Straight design for common and universal applications.

- Robust construction for reliable strength.

- Galvanised finish for corrosion resistance.

Recommended Uses:

- General industrial and manufacturing.

- Agriculture and livestock.

- General purpose applications.

2. The UNIQ DIN 5685/A chain:

UNIQ chain DIN 5685/A is a versatile choice for a wide range of pulling, traction and signal applications. Its galvanised design and robust construction ensure optimum performance in a wide range of industrial and commercial environments. DIN 5685/A UNIQ chain complies with the most demanding regulations and is available in galvanised steel and stainless steel versions to suit different conditions and requirements.

Key features:

- Complies with DIN 5685/A for pulling and traction applications.

- Available in galvanised steel and stainless steel.

- Galvanised finish for corrosion resistance.

Recommended applications:

- Pulling and traction applications in industrial environments.

- Signalling and marking in work areas.

- Nautical, fishing and livestock applications.

3. UNIQ Grade 80 chain:

UNIQ Grade 80 chain is designed for lifting and pulling applications where superior strength and optimum safety are required. Manufactured from high strength alloy steel and treated for durability, this chain offers exceptional performance in the most demanding conditions. UNIQ Grade 80 chain meets the highest quality standards and is the preferred choice for heavy lifting and industrial applications.

Key features:

- Manufactured from high strength alloy steel for increased traction.

- Treated for durability and resistance to wear.

- Manufactured to the highest quality standards.

Recommended Uses:

- Heavy lifting in industrial and construction applications.

- Pulling and traction applications in industrial environments.

- Projects requiring high strength and safety.

In conclusion, the UNIQ range of chains offers a solution for every need, from common and universal applications to heavy lifting and safety at work. By choosing the right chain for each application and following best installation and maintenance practices, you can ensure optimum performance and unrivalled safety in every operation.