All you need to know about UNIQ Steel Wire Rope

Basic components, structure, composition, materials and much more. We explain it all below.

An overview of their evolution and characteristics

Concerning their development, UNIQ steel wire ropes, among others, show a rapid and constant progress in the development of their manufacturing technology. In order to balance hardness, resistance, crushing, fatigue and corrosion, current developments focus on the quality and materials used to manufacture the wires.

This is why the main characteristics of steel wire ropes are based on their composition, in other words, the number of wires, their arrangement, the materials used in their manufacture and the formation of the strands and the winding, so that they acquire greater or lesser resistance depending on these elements.

Basic components of a steel wire rope

A) Core: Central element of the steel wire rope whose function is to provide firm support to the strands. It can be of two types:

· Textile or fiber: You will be able to distinguish them because the letters FC will appear in their name. This type of cable will have greater flexibility, but less resistance in environments with high humidity and/or temperature.

· Metallic or steel: They will have the letters WSC in their name. In this case, they will have less flexibility, but will be much more resistant in environments with high humidity and/or temperature.

B) Cord: Made up of a number of wires wound in a helical pattern and twisted around the core to form the final product.

C) Steel wire: This is the main component and its thickness and the way it is twisted determine its tensile strength.

Steel wire rope structure

If you check the UNIQ Steel Wire Rope category of our website, you will see that each one of them has a 3-number designation. What does each one refer to? Let's see, for example, the structure of the Galvanized Steel Wire Rope - 6 x 7 + 1 (FC):

The first number corresponds to the number of strands, the second number to the number of wires per strand and the third to the type of core, which can be 0 (metallic core / WSC) or 1 (textile core / FC). In this case, this galvanized steel wire rope has 6 strands, each of them composed of 7 wires and has a textile core.

Then we have another type of designation that does not have a final number. As the name itself indicates, it is no longer a set of cords forming a cable, but a single cord. That is why it has no core, no number at the end, and no identifying letters (WSC / FC). This is its structure:

It is 1 cord formed by 19 wires and has no core (because it has no third number).

Following the same scheme, we can find from the simplest steel wire rope systems intended for more rudimentary use, such as in agriculture or gardening, to the most complex and large systems intended for the loading of heavy elements, such as in lifts or large cranes.

Types of coiling

In other words, in which direction are the cords and wires of the steel wire ropes coiled? There are two types of coiling:

· Crossed: The most common. The cords are coiled in the opposite direction to the wires, and can be in both directions (crossed right and crossed left). This type of winding makes the wire rope more resistant to crushing and deformation and easier to handle.

· Lang: When the direction of the wires is the same as that of the strands.

They can also be coiled from right to left or vice versa (Z or S) for greater strength due to their torsional resistance.

Types of steel wire ropes

In the field of steel wire ropes there are different types, which differ in their characteristics and structure. Here are two of the most common types of wire ropes in the UNIQ range.

· Normal: Versatile but not very flexible, normal ropes have helical cylindrical wires around a core. They distribute the tensile load evenly with progressively increasing layers.

· Anti-Spin: Designed to counteract unwanted twisting of wire ropes, anti-spin ropes balance the tensile moments between the ropes. With a common design such as multi-strand (19×7+0), they effectively minimise the twisting effect.

For example, the Galvanized steel wire rope - 19 x 7 + 0 (non-rotating) has this type of winding. Let's see its structure:

It consists of 2 layers: an inner layer of 6 cords (core) and an outer layer of 12 cords (together they total 19 cords), each of which consists of 7 wires and has a metallic core (1) which, in fact, corresponds to the second layer of cords. In addition, the cords of each layer are wound in different directions. Thus, the cords compensate for stresses and eliminate the tendency to rotate on themselves due to the tension exerted by the suspended load.

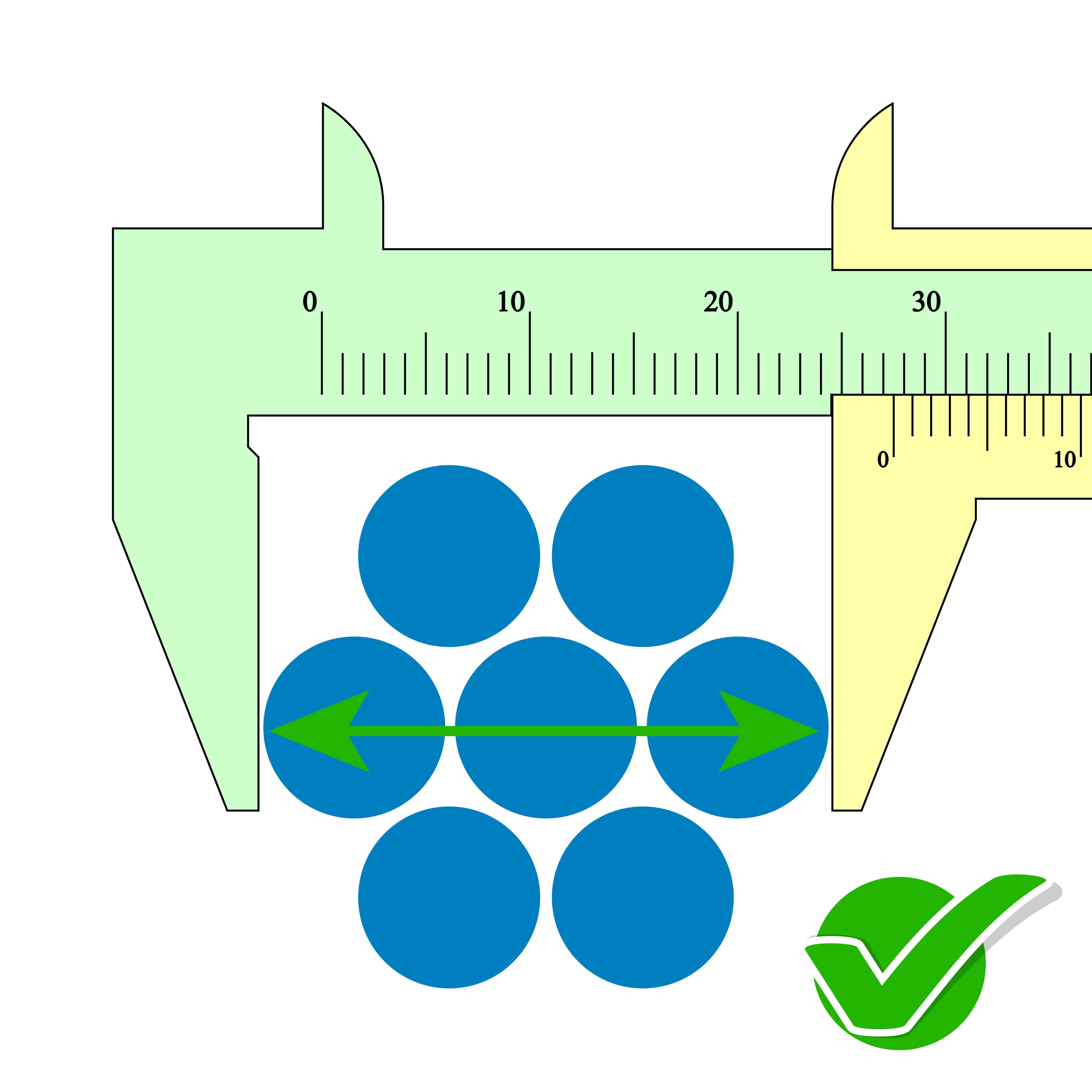

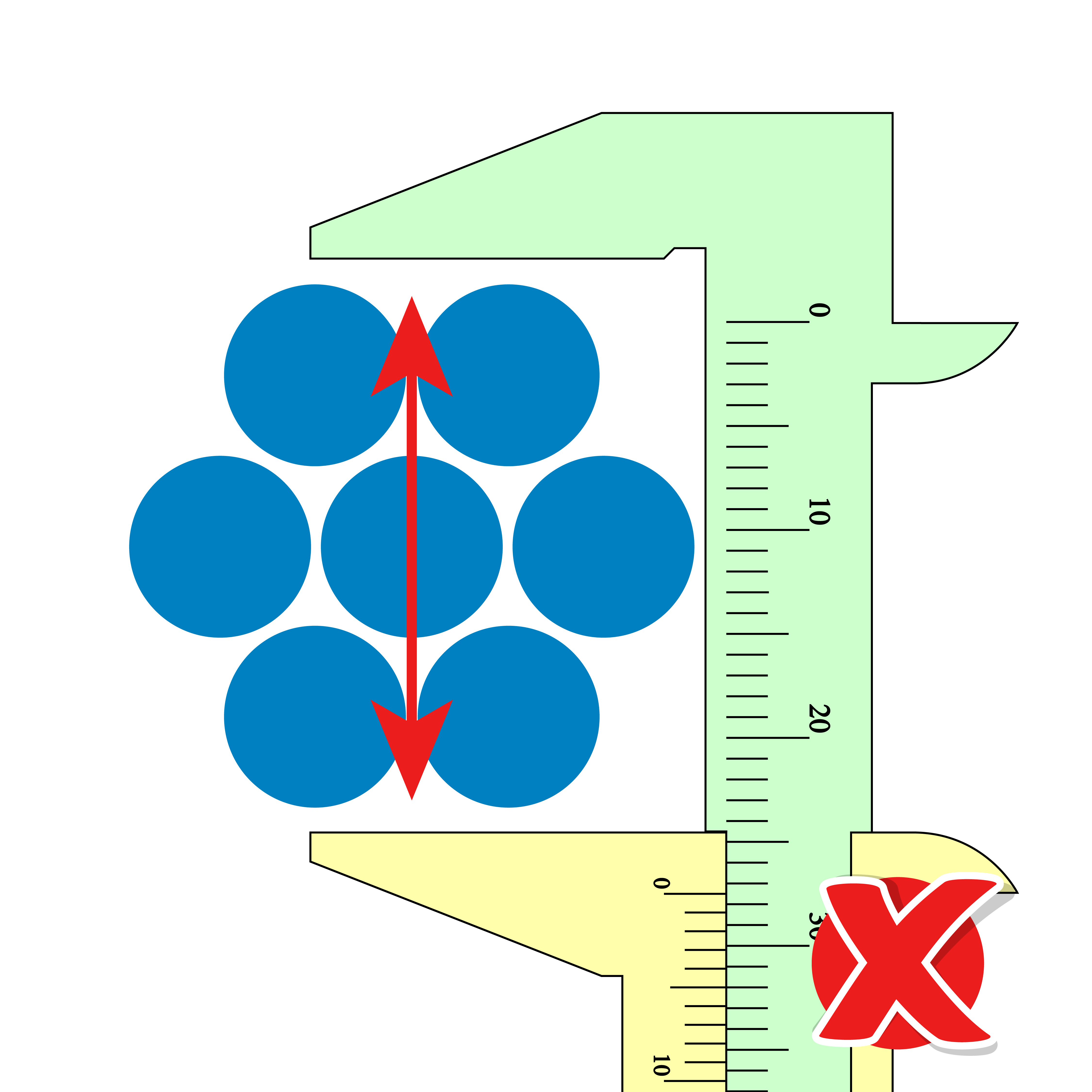

Steel wire rope diameter

It is usually expressed in millimeters (mm) and should be measured as shown in the picture:

And we must differentiate between:

· Nominal diameter: Used to identify the cable, it does not necessarily have to be the real value of the cable.

· Useful diameter: Real diameter of the cable, it must always be larger than the nominal one and can never be higher than +8% (EN12385).

Wire rope materials

UNIQ Steel Wire Rope is available in 3 materials:

· Galvanized steel C60: Manufactured with electric galvanized steel wire.

· Stainless steel AISI 316: High resistance to corrosion.

· Plasticized PVC: C60 galvanized steel plasticized in transparent PVC.

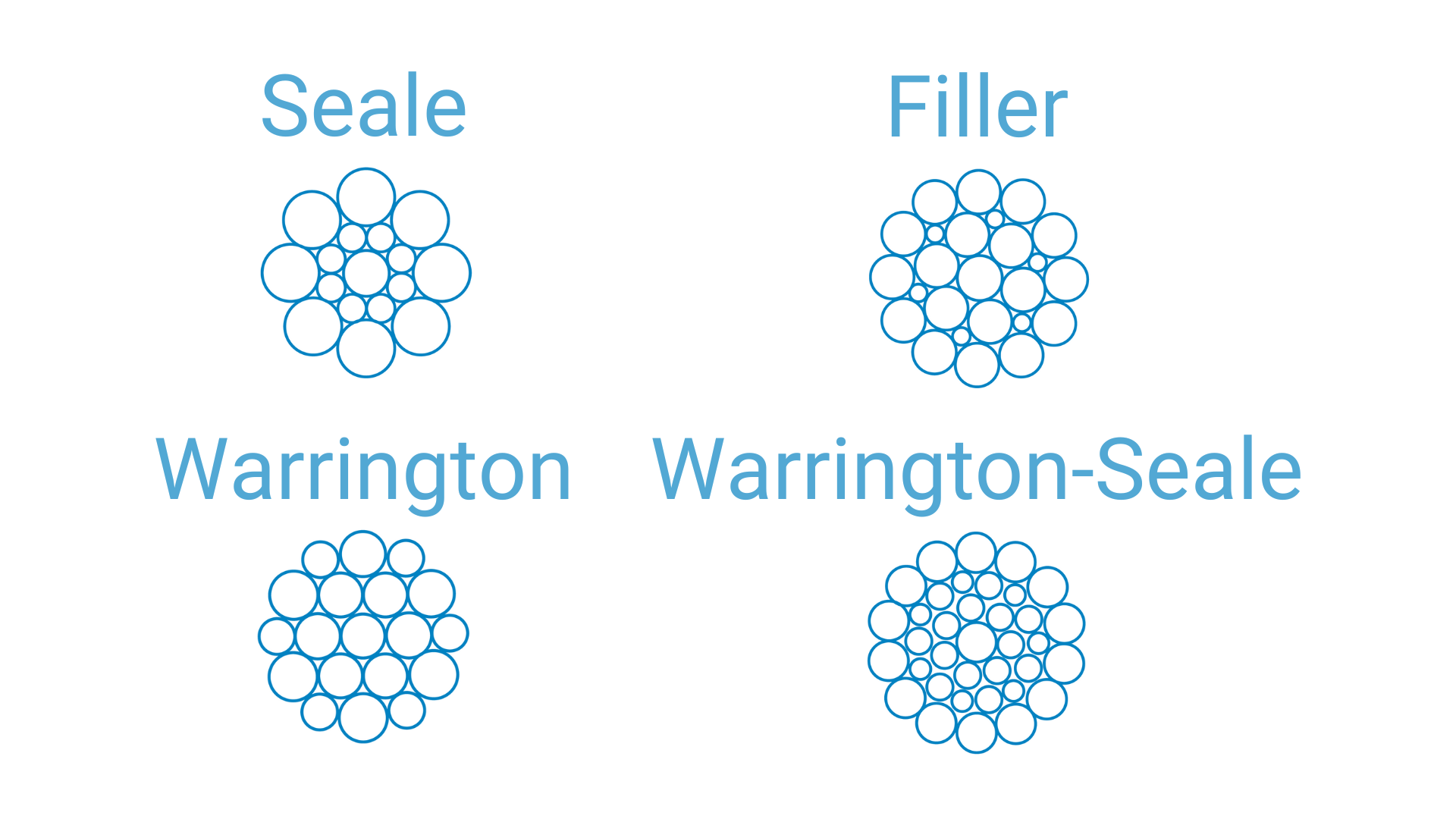

Composition of steel wire ropes

The construction of UNIQ steel wire ropes is based, among other things, on a set of wires that form a cord and are wound around a core or core wire. In this way we can vary the arrangement of these wires and strands to obtain different compositions.

Taking into account the number of strands, the thickness of the wires and the geometric position of the terminations in the strand, there are four types of construction.

· Seale (S): Made up of two layers around a core, with the same number of wires in each layer. It should also be noted that all the wires in each layer are the same diameter, so that one layer lies on top of the other, providing a secure and reliable hold.

· Filler (F): Formed by two layers of wires of the same diameter around a central wire. The inner layer has half as many wires as the outer layer, so we add a third layer of smaller wires to fill the gap between the first and second layers.

· Warrington (W): Formed by two layers around a central wire, this is characterised by the fact that the inner layer has a single diameter, while the outer layer combines two types of diameters.

· Warrington-Seale (WS): Consists of two different constructions at the same time, a combination of layers, each following a different pattern, alternating between Warrington and Seale construction.

How to install UNIQ steel wire ropes

We also invite you to explore the diversity of our products through a series of comprehensive video tutorials on our website. From the most commonly used clip cable ties to specialised shapes such as single, oval and double, we will guide you step by step to ensure optimum installation. Or immerse yourself in the versatility of our aluminium ferrules, learn the secrets of perfect tensioning with our wire stretcher and discover the wide range of cable and chain accessories.

Our in-depth tutorials will give you the tools and knowledge you need to carry out efficient installations, ensuring the durability and safety of every component. Become an expert installer of our products and get the most out of their performance!

We hope we have clarified some of your doubts and if you have any questions do not hesitate to contact us, we will be happy to help you.

See you next time! 😊